Table of Contents

Technology has progressed substantially throughout time. Developing industries utilize a range of equipment in their everyday operations to increase productivity. Fillers, for example, are used in a range of industries and are a valuable resource for these companies.

What are the Uses of filling machine?

Filling machines are used to fill a range of products, including food and beverages. They’ve been used to fill bottles or pouches, depending on the product.

Liquid fillers, also known as liquid filling machines, are important pieces of equipment in industries including cosmetics, pharmaceuticals, and food and beverage, where liquids must be packed in various containers. Liquid filling machines enable liquids to be packed into storage tanks rapidly and efficiently with less waste and at a faster pace. Consider how this technique might be performed manually in the workplace.

How much liquid would be wasted due to leakage, and how long would it take to use bulk packaging?

Liquid filling machines are employed as a consequence. Modern liquid filling machines are the most efficient means of packaging liquids in factories in less time and with less manpower. They come in a variety of elegant designs with easy-to-use controls and functions. In the absence of these gadgets, a liquid filling machine may easily and rapidly perform massive liquid filling operations in industries, obviating the need for a significant number of workers to finish the process. It’s often used for viscous liquids like syrup, oil, and wine, which need this method of filling containers. The liquid filler is a very effective solution for putting such liquids into their respective containers. The filling mechanism fills the liquid due to gravity. The liquid fills the container due to its weight. The equipment may have a tank, bottle, or container to fill the liquid. These containers go through a cycle of being filled with liquid and then being ready to be packaged.

What are the Filling machine applications?

A filling machine is a type of packing machine that attempts to measure a product from bulk according to a prescribed level, such as container level, mass, or volume. After acquiring the measurement, the machine packs the contents into a box, bag, or other packaging containers. Filling machines are utilized in a wide range of industries and enterprises. Filling machines come in a variety of shapes and sizes, and they’re used in a variety of industrial settings to perform specific tasks. For example, filling machinery designed for bottled water cannot be utilized to fill cosmetic cold cream.

For example, liquid filling equipment used in the pharmaceutical sector may not be acceptable for use in the food industry. Filling machines may be found in a wide range of industries, including food, pharmaceuticals, beverages, and chemicals. The filling machine is chosen based on several factors, including viscosity, chemical compatibility, product size and form, and environmental concerns. Bottle filling machines are used to fill items that need to be packed in bottles.

These gadgets are available in a wide range of forms and sizes. For small bottle filling machine activities, the overflow automated filling machine is preferred. It’s mostly used to fill low-viscosity fluids. For goods that can be pumped, an automated servo pump is used. A bottle filling machine can be used to fill liquids with a medium or thick viscosity. The food, beverage, and pharmaceutical industries are the primary users of bottle filling machines. Tube filling machines are used to fill tubes with the needed product.

They also use unique sealing techniques to prevent the contents of the tubes from spilling out. The fold and crump method is used to seal metallic types. Before being sealed, the plastic tube is gently heated. In a number of industrial contexts, the tube filling machine may be used. Grease, food, creams & lotions, pastes, powders, and glues are only a few examples of what may be filled. Automatic tube filling machines are used to load, fill, and seal plastic or metal tubes and exist in a range of shapes and sizes.

Vial filling machines use vials, desiccant stoppers, and flip-top packaging throughout the filling process. Filling vials with liquids or powdered ingredients is possible using vial filling machines.

In the pharmaceutical and food industries, vial filling machines are often employed to ensure product packing efficiency. Because of the single track bottle movement and pneumatic bottle holding mechanisms used during liquid filling, vial filling machines are well suited for heavy filling operations. A vial liquid filling machine may fill a bottle, tube, or any other container with a different volume of liquid. They’re employed in the pharmaceutical industry to ensure that the right quantity of medicine is packed to avoid overdosing or standard reduction. The material used in the building of any filling machine determines its strength and accuracy.

What are the Different Types of Filling Machines?

Liquid filling machines come in a range of forms and sizes, based on the level of automation, the containers into which the liquid will be placed, and the number of heads the machine has to fill a certain number of bottles or containers at once.

Fully automatic liquid filling machines, semi-automated liquid filling machines, twin head liquid filling machines, four head liquid filling machines, six head liquid filling machines, eight head liquid filling machines, liquid filling machines for vials, liquid filling machines for bottles, electronic liquid filling machines, liquid filling machines with capping features, and liquid filling machines with rubber stoppers are some of the most commonly used types of liquid filling machines for in-line filling.

Devices for filling heavy liquids, such as oils, are also available on the market today. Examples include edible oil filling machines, culinary oil fillers, oil fillers for lubricating oil filling, and other equipment. Different types of equipment are used in the filling of various substances. Many firms use these fillers because they make it simpler for producers to fill bottles and other containers.

What kind of liquid filling machines are there?

Liquid filling machines are available in many different forms and sizes.

The most common liquid filling devices are as follows:

Manual liquid filling machines are liquid filling devices that do not need electricity. These are suitable for small-scale enterprises. Semi-Automatic Liquid Filling Devices—these machines fill liquids without dripping using a syringe, piston, and nozzle. This is how cleaning detergents and pharmaceuticals are created. Liquid Filling Machines that are fully automated.

These machines can handle large-scale operations and can fill liquids of any viscosity. This is a word used to describe food products. Liquid Filling Machines in a Single Line-This machine pours different liquids into containers arranged in a single line using the conveyor system. It’s ideal for products in the food, dairy, and cosmetics sectors.

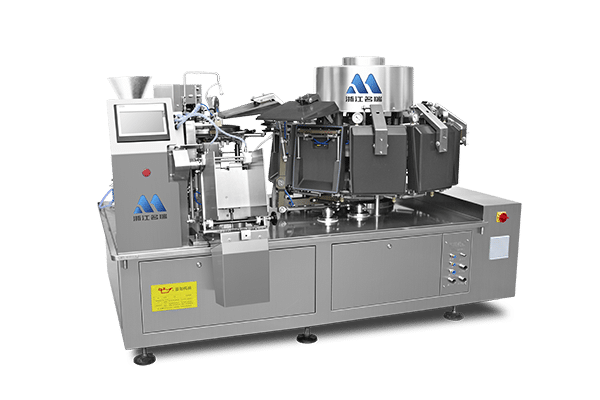

Rotary Liquid Filling Machines transfer containers around a succession of circular stations, each of which performs a particular operation such as filling, sealing, or capping.

This kind of liquid filling equipment is used in the beverage, culinary, automotive, and personal care industries. A twin head liquid filler machine, a four-head liquid filling machine, a six-head liquid filling machine, and eight head liquid filling machine, a liquid filling machine for vials, a liquid filling machine for bottles, an electronic liquid filling machine, a liquid filling machine with capping, and a liquid filling machine with rubber coppering are all examples of these machines.

There are edible oil filling machines, culinary oil fillers, lubricating oil filling machines, and much more.

What are the Operating Principles of Different Filling Machines?

- What are THE LIQUID FILLING MACHINE PRINCIPLES?

The liquid filling mechanism operates when the pressure is high. Liquid pressure filling happens when the pressure in the liquid reservoir equals the amount of air in the container, and the liquid flows into the bottle based on its own weight.

These liquid fillers are easy to use and control, enabling you to precisely fill gallons or containers with the liquid you want. There’s a filling mechanism that allows the machine to adjust to different bottle sizes without replacing components, as well as a “No Bottle-No Fill” mechanism that stops the process if there’s no bottle on the belt.

- What is the PRINCIPLE OF DIGITAL LIQUID FILLER?

Digital liquid fillers are one of the most in-demand liquid fillers in the current environment due to operator-friendly properties that make it simpler for the operator to create the best results at a quicker pace. On digital liquid fillers, every filler function, such as indexing the diving nozzle and system control, is available through a simple operational interface. The computerised liquid filling machine needs a steady power source and will adapt to a low power supply in certain instances. Before the product is finalised, these automated fillers inspect bottles and pouches for any faults.

- What is the PRINCIPLE OF THE MAJOR VIAL FILLING MACHINE?

The vial fillers are cost-effective since they take up less space and may be stored in a small area depending on the size of the regulators, and they can be operated by only one person. Sensors in vial fillers detect empty vials and reject them.

The weight checker mechanism in these fillers has a function that assures that each vial has the same weight. One of the actions of these vial fillers is to load the vials, which are then carried via an isolated region.

- HOW ARE DIFFERENT PRINCIPLES APPLICABLE TO POWDER FILLERS?

To ensure high production and efficiency, powder fillers are the most often utilised fillers in the pharmaceutical sector. As a result, there is a lot of demand on the market for them.

- Powder filling machines have an average stroke rate of 108 strokes per minute.

- These powder fillers are either semi-automatic or fully automated, and they work efficiently to provide the best results.

- Most companies need a machine that produces at a constant rate throughout the day, thus the filling speed in these machines is always higher.

- Because the motor provides the required push for the rotating elements, the filling drive mechanisms are compatible and user-friendly.

- WHAT IS THE FUNCTION OF THE AMPOULE FILLING MACHINE?

Ampoule filling machines are used in the pharmaceutical sector to fill ampoule capsules. Businesses that desire to invest in high output can benefit from these gadgets.

Some of the attributes that make these ampoule filling machines the most preferred option are as follows:

One of the most important features of ampoule filling machines is that they may entirely encase the product in inert glass, eliminating the need for a rubber stopper or any other material that comes into direct contact with the drug.

Ampoule fillers are used to fill ampoules, and the speed varies based on the equipment manufacturer and the ampoule machine’s important mechanism. For proper vial identification, several ampoule coding systems need ring banding to complete the whole ampoule tip. The filling range of ampoule filling machines is commonly 1 to 20 milliliters9.

Ampoule filling and sealing machine

The following are some examples of different types of filling machines and how they work. These filling machines are used to fill containers/gallons, bottles, pouches, and vials in a number of industries, including pharmaceuticals, milk factories, cold storage, and others. These are a fantastic investment for attaining exceptional business results.

- What is The Importance of a Filling Machine for Liquids?

Despite their ubiquitous use, liquid filling machines provide a substantial contribution to the production line, and their many catering features enable any firm to save money and enhance revenue.

Some of the benefits of employing a liquid filling machine are as follows:

Consistency and Quality –

It is possible to skip using measuring instruments, which saves time and eliminates inconsistencies during bottling, making transportation easier. Depending on volume, weight, level, and other factors, liquid filling machines ensure that each container receives the same amount of product.

Easy-to-use and quick-to-load operating systems

Using relative fillers and machines with cappers makes it simple. Because they feature input parameters such as indexing times, fill times, and pump speeds, filling machines are very versatile. These machines can fill both thick and thin liquids, which is beneficial for businesses with several manufacturing lines looking for additional income sources.

Benefits of upgrading – They may be upgraded without replacing the liquid filling equipment in terms of a company development model. Depending on the kind, most industrial filling machines contain four to six filling heads. This number may be raised over time, and some models contain as many as sixteen fill heads, making it a very scalable option.

Time and energy are saved–

You save money on personnel while also saving money on electricity since they are built to live longer and use less energy.

Conclusion

With so many advantages, filling machines are unquestionably critical equipment that every business should have in their manufacturing facilities to provide speedy and efficient filling and packaging applications.

It is essential to choose a filling machine that meets the needs of the manufacturing facility in order to guarantee the machines work well. For instance, the fluids to be filled vary by industry, as does the viscosity of the fluids to be filled. In this scenario, a machine that is adequately suited for the viscosity of the liquid to be loaded would operate better.

The required speed of the machine and the characteristics of the machines are also critical elements in choosing suitable equipment for the filling activities. This article informs readers about the value and advantages of filling machines in the packaging industry.